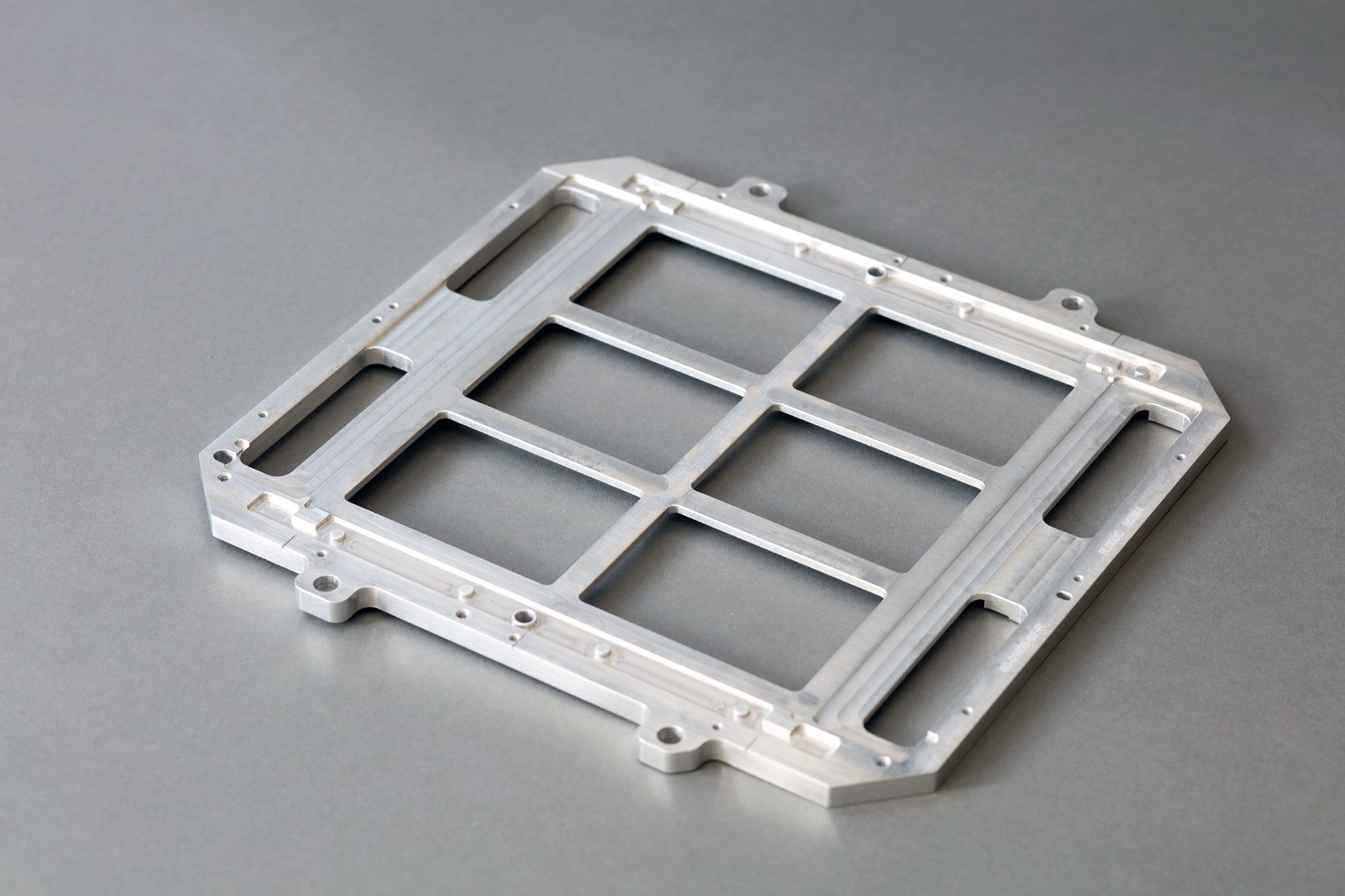

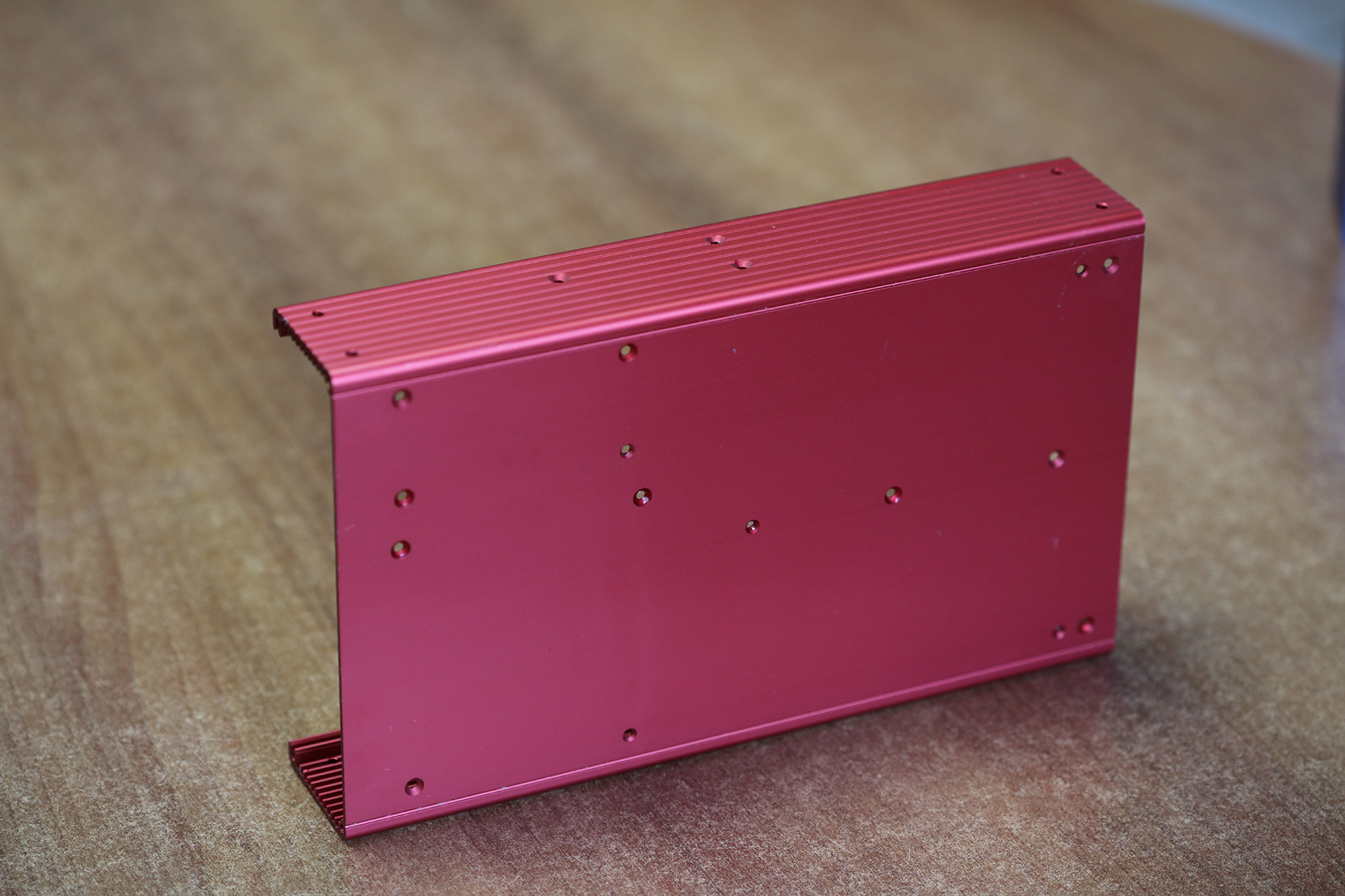

We ensure we are always meeting the highest quality standards. ASTM Standards, including coating thickness, coating weight, density and die stain tests are performed. Sample analysis is done on a bi-weekly basis by an external lab. Tank concentrations are checked, controlled, and documented daily. C of C’s available upon request.